Case Study: We will do whatever it takes to keep you up and running.

Whatever it takes: ABOVE AND BEYOND FOR EMERGENCY REPLACEMENT PUMP

R. A. Ross rep’s “Never give up”

attitude saves client from weeks

of downtime and loss of money.

We had a customer with a Dean R4140 2x3x8.5 hot oil pump that was down and they were faced with an 8-10 week leadtime. The factory did not have castings for one of the parts they needed to repair their existing pump or for a replacement pump. With this pump down, part of the customer’s plant was down and costing them money minute by minute.

Knowing they needed a pump we started exploring options we had at our disposal. Our first option was to find another pump just like what they had. We tried several other Dean distributors to see if they had a pump in stock with no luck. Next we tried a few of the refurbishing dealers we work with to see if anyone had a rebuilt pump; no luck. Facing a third strike we turned

back to Dean and the RA Series Air Cooled Hot Oil Pumps.

The Dean RA3000 series air cooled hot oil pumps are dimensionally interchangeable with with the R4140 series pump piping and baseplate dimensions envelope. Furthermore they share the same hydraulic characteristics meaning they would provide the same flow and pressure as the existing pump.

The last hurdle in being able to offer the RA3000 pump is that it will not handle as high of a temperature as the R4140. Luckily the customer’s process was still well within the limits of the RA3000.

After going back to Dean to find they did not have a pump in stock or the ability to expedite one, we again turned to some of our other fellow Dean distributors. The RA3000 series pumps are a very common pump for OEM’s to use in hot oil system packages and are more commonly stocked by Dean distributors. After several calls we found a fellow distributor that had one in stock and agreed to help us out. We worked quickly with the customer to get an order placed and have the pump shipped overnight to get them back up and running.

“ Brad, you have gone above and beyond!”

Gary Morrison

Maintenance Planner

Catalyst Division

Clairant Corporation

The pump arrived and was installed quickly since it was a drop in getting them back on line with minimal downtime.

ABOUT BRAD

Brad, our inside representative who solved this problem has been a part of our team for 7 years. His attitude, like all our team, is to do whatever it takes to keep your company up and running.

In this case, Brad put everything else on the back burner to get this issue taken care of as the customer was losing a lot of money and was facing a very long down time. As you can tell by the summary, Brad (and all our team) has extensive knowledge of the products we sell, as well as what your needs are. This comes from ongoing, continuing education from our product manufacturers.

We hope that “whatever it takes” philosophy helps us keep customers for life. That is our goal. Not just a sale.

If you’d like more information on other case histories, please visit our website at www.raross.com. Chances are, we’ve helped solve a problem that you may have had or might face in the future.

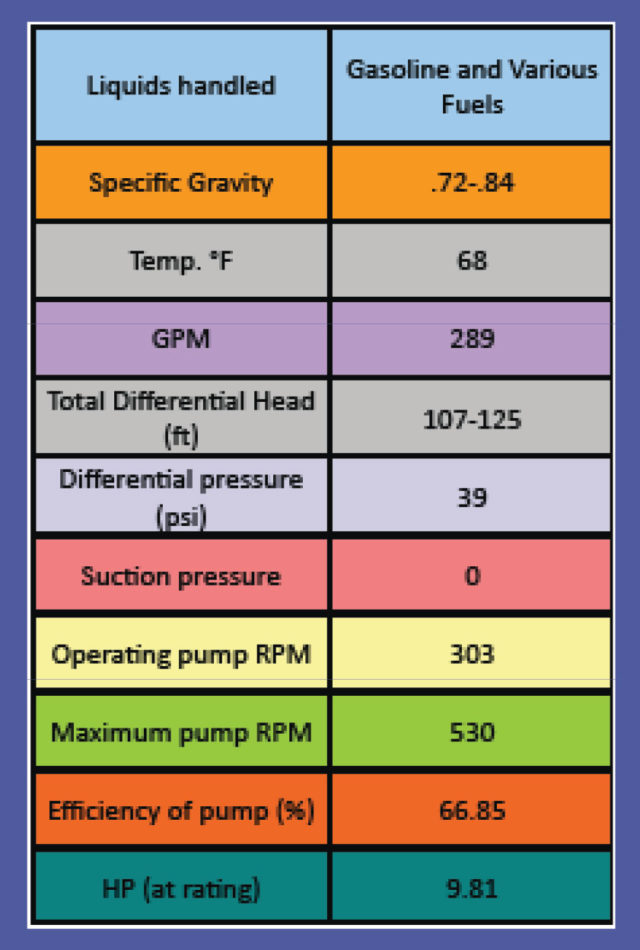

Situation/Solution: A large oil company requested a Blackmer pump that would be used for “proving” gasoline, ethanol, diesel and biodiesel at several of their facilities. The specifications were listed as seen in the chart to the left.

Situation/Solution: A large oil company requested a Blackmer pump that would be used for “proving” gasoline, ethanol, diesel and biodiesel at several of their facilities. The specifications were listed as seen in the chart to the left.

Application

Application