Case Studies

CASE STUDY

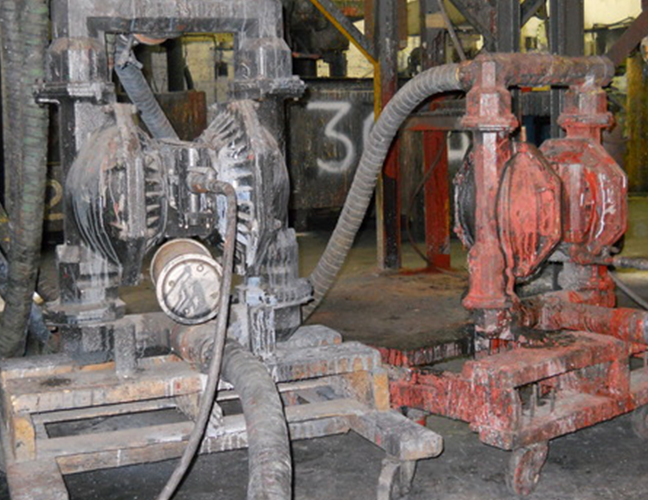

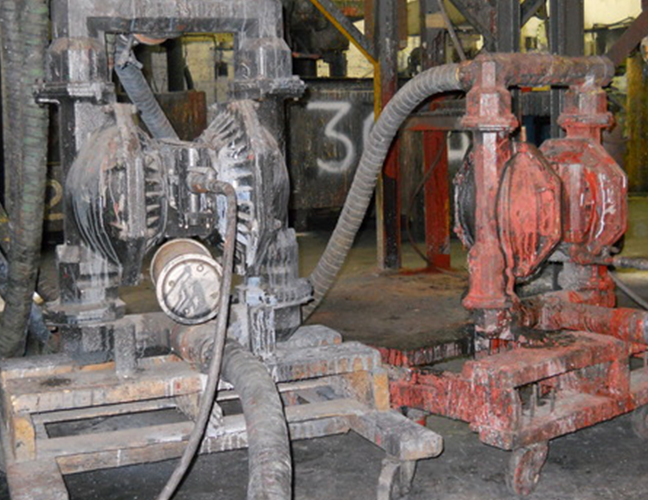

Air operated Diaphragm pump ball check was deformed and pushed through seat into fluid cap causing pump failure.

Problem

Shock and back pressure sends 2 1/2” check ball into 2” hole causing weekly pump repair.

Situation

�A local industrial plant which makes metal flake pigment for the automotive paint and cosmetic industry was having a real issue with some air operated diaphragm pumps. The pumps were 2” pump running well within their range of operation, but would experience a tremendous shock of back pressure when the system was shut down. The product being pumped was a mineral spirits and aluminum powder slurry at ambient temp.

We were receiving pumps weekly that would have the check ball lodged into the fluid cap of the pump. This was a very strange site to see as the check ball is 2½” in dia. and the hole in which it was forced through was only 2” in dia. The balls were a Nitrile rubber and not easily deformable.

View of fluid end cap (Rotated 180°) where ball was pushed through seat into end cap.

To remove the balls from the fluid caps of the pump we had to drill them out. The balls could not be driven out with a punch and hammer and the use of a hydraulic press risked deformation of the fluid cap itself.

There were no signs of chemical attack or deformation due to temp, so we recommended the use of a Blacoh dampener to absorb the shock from the system that we suspected was forcing the balls into the diaphragm chamber.

After installation of the dampener, which has been nearly 6 months to date, the pump has not been touched. Repairs and downtime from pump change outs have been eliminated on this line and the customer is looking to install the dampeners in other locations to save wear and tear on the pumps and piping system.

We love tackling and solving the toughest problems. Put our knowledge, training and skills to work for you today. Call us…we’ll keep whatever you process flowing.

Download the case study

Case Studies

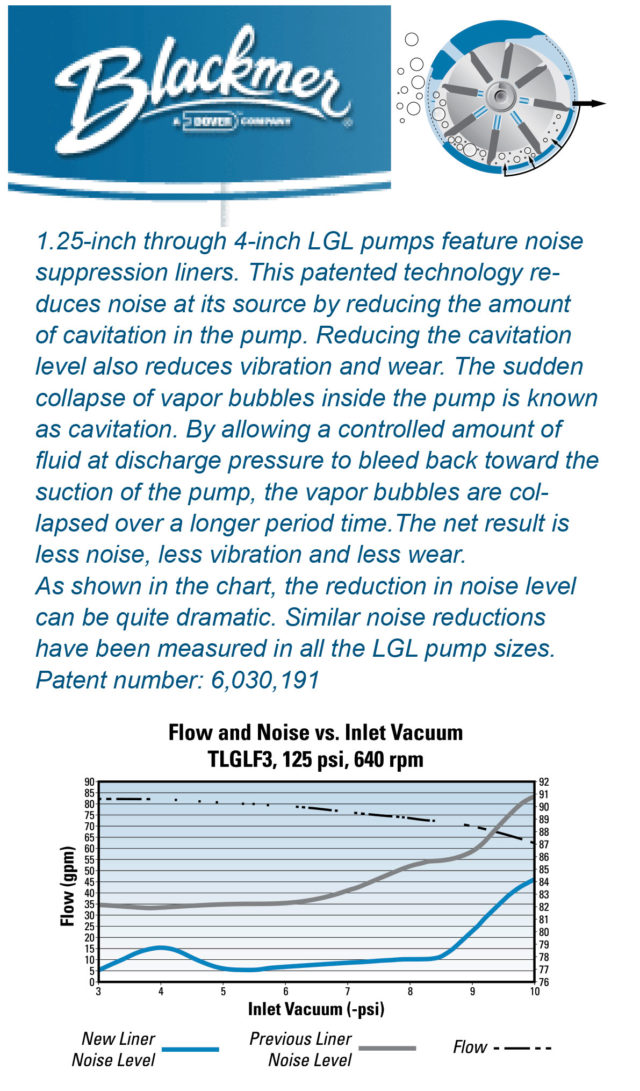

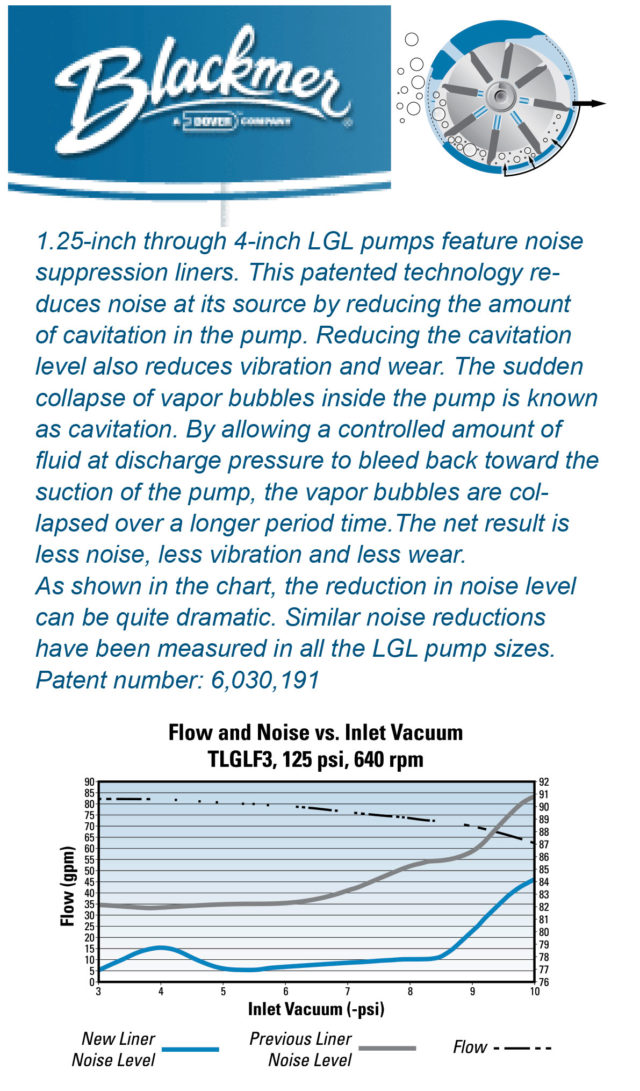

BLACKMER SOLUTION

Problem

When Gusher centrifugal self primers kept loosing prime and seals, another solution was needed and was needed fast!

When the Gusher centrifugal self-primers kept losing prime and seals another solution was needed and was needed fast! The original pumps, part of an OEM packaged skid, removed a mix of water with some heavy hydrocarbons to opposite of mostly hydrocarbon and some water from a liquid/vapor separating vessel.

Application

Application

- Pumpage – Ambient temp water with some heavy hydrocarbons to mostly hydrocarbon and some water

- Some mixed phase pumping when some hydrocarbons cause vapor in suction (flow reduction may be realized base on amount of gas entrained in liquid) 20gpm @ 135psig discharge (0-5psi positive tank pressure)

Solution

- Blackmer liquefied gas pumps with custom bases and reducer/motor setup.

- Pump: Blackmer SGLD2 ductile iron sliding vane pump with carbon vs. silicon carbide mechanical seals, HNBR elastomers, Duravane vanes, 2” NPT flange connections and Blackmer’s cavitation suppression liner (LGL &SGL pumps)

- Reducer: NORD SK12 with 4.93:1 ratio for 355rpm output speed with 1750rpm motor.

- Motor: Marathon Premium Eff. 5hp 3/60/230-460/1750rpm TEXP footless with 2:1 turndown.

- VFD Controller: Toshiba ASD in NEMA 1 enclosure.

Formed Steel Base and Guard: The base was custom designed with a minimum height to allow for as much NPSHa as possible. The length and width of the base were also made specific too fit as far down into the skid as possible to reduce piping arrangement augmentation.

After only a short time in service, the benefit of the assemblies was apparent; no more pump failures, no more vapor lock, increased flow, and shortened cycle times. Shortly after this success more assemblies were ordered to retrofit other skid packages to utilize the Blackmer SGLD2 pump and all the benefits the pump provides in the application.

Download the case study

Case Studies

R. A. Ross saves customer $200 per seal.

Our focus is on saving you time and money

We have a customer who called asking if we could repair an Eagle Burgmann seal that they were paying $400 for.

After some research, we discovered that Eagle Burgmann would typically not repair this type of seal.

However, we found that we are able to offer this same exact Eagle Burgmann seal for $200.

Our profit margin on this type of solution is minimal, but that’s not why we are in business. Our focus is on helping our customers save time and money. Our job is to help keep you up and running.

Give us a call and let us find a solution for you!

Download the case study

Case Studies

CASE STUDY

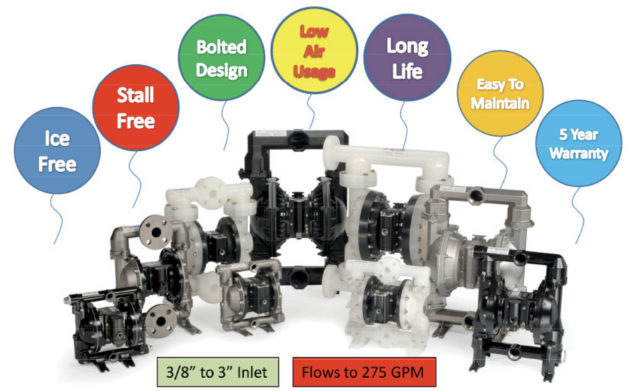

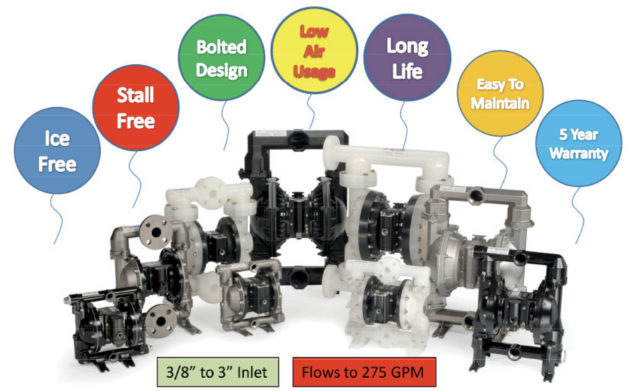

Problem: Small non-electric pump needed to remove water from mine shafts.

Ross & Associates solves problem of high cost of removing water from mine shafts

A western KY coal mine was looking for a small, portable, non-electric pump to remove water from mine shafts. The electric pumps that they would typically use for dewatering were cost prohibitive due to the IMSHA explosion proof safety guidelines that all mine operations must adhere to. Since air lines were already in the mine for drilling tools and other equipment, an ARO air operated diaphragm pump was an easy choice. We were able to supply a small 1” ARO pump that suited the customer’s needs perfectly. Word quickly spread to other mining operations in the area which generated more sales of the ARO product.

A western KY coal mine was looking for a small, portable, non-electric pump to remove water from mine shafts. The electric pumps that they would typically use for dewatering were cost prohibitive due to the IMSHA explosion proof safety guidelines that all mine operations must adhere to. Since air lines were already in the mine for drilling tools and other equipment, an ARO air operated diaphragm pump was an easy choice. We were able to supply a small 1” ARO pump that suited the customer’s needs perfectly. Word quickly spread to other mining operations in the area which generated more sales of the ARO product.

Our job is to help keep you up and running.

R. A. Ross & Associates offers over 150 years combined experience.

Ingersoll Rand ARO offers a wide range of fluid technologies for today’s demanding industries and applications.

Diaphragm Pumps

- Aluminum, Cast Iron, Stainless Steel, Hastelloy-C

- Groundable Acetal, PVDF (Kynar), Polypropylene

- 1/4” to 3” ported • Flow rates up to 275 gpm

- Santoprene, Hytrel, PTFE, Viton, Nitrile

|

|

Diaphragms Piston Pumps

- Carbon Steel, Stainless Steel

- 2-Ball, 4-Ball, Chop-Check, Oil & Grease Pumps

- Pressure ratios up to 65:1 (100:1 for grease pumps)

- Flow rates up to 32.8 gpm

- UHMW-PE, PTFE, and Leather Packing seals available

|

|

Specialty Application Pumps

- Pit Boss ™ Dewatering Pumps (1 1/2” – 3” ports)

- Powder Transfer Pumps (2” & 3” ports)

- Flex-‐Check™ Pumps (3/8” ports)

- Sanitary Transfer Pumps (1” – 3” ports)

|

|

Pneumatic Valves & Cylinders

- 2 way, 3 way, & 4 way valves

- Up to 1” ports

- Pilot, solenoid, and/or mechanical actuators & returns

- Single-‐ and double-‐acting cylinders

- Up to 10” bore, various stroke lengths available

- Aluminum, Stainless Steel

|

|

Download the case study

Case Studies

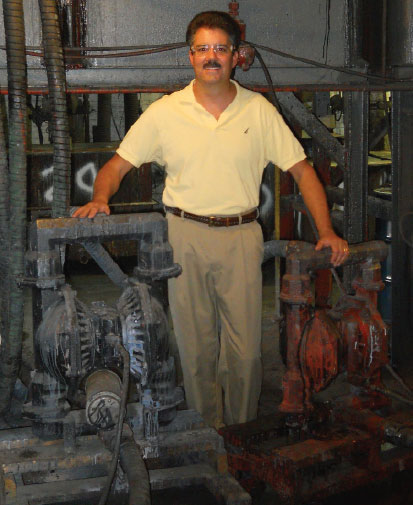

Satisfied R. A. Ross and Associates customer using Ingersoll Rand Aro pumps for over 20 years

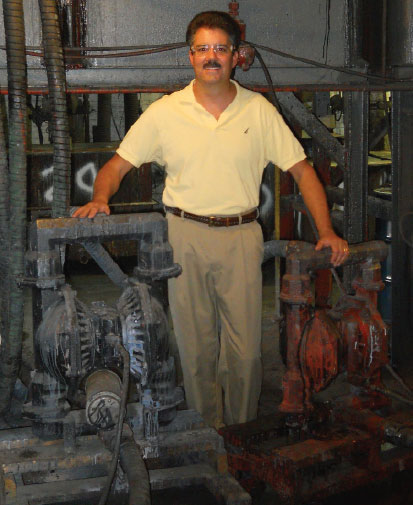

Steve Marcus, VP Marcus Paint Company, with two of the many I-R Aro Pumps they use.

Marcus Paint has been manufacturing paint since 1853 and supplies coatings to industrial companies all over the US and Mexico.

We manufacture paint for every kind of product you can think of, metals, plastic, etc., and, as you can imagine, mixing different resins and pigments requires many different solvents.

Solvent temperatures vary from 35º to 185º. That can tear up diaphragms. I-R Aro pumps can stand up to that kind of abuse.

Without pumps, we shut down. Pumps are vital to mixing paints.

“We pump several different types of solvents. Solvent temperature extremes tear up diaphragms. Aro Pumps and Ross & Associates solved our problems. No more pump failure.”

- Marcus Paint pumps from 500 to 6,000 gallons of paint daily

- Marcus Paint has used Aro Pumps since 1988

CASE STUDY INSIDE

Paint manufacturer says; “Without pumps, we shut down.” How reliable are your pumps?

WHY INGERSOLL RAND ARO PUMPS?

Only I-R Aro Pumps can stand up to the abuse that companies like Marcus Paint Company put them through. Aro Pumps are designed to handle extreme temperature differences, various chemicals and still operate round the clock. Less down time means more profit to any company’s bottom line.

Download the case study

Application

Application

A western KY coal mine was looking for a small, portable, non-electric pump to remove water from mine shafts. The electric pumps that they would typically use for dewatering were cost prohibitive due to the IMSHA explosion proof safety guidelines that all mine operations must adhere to. Since air lines were already in the mine for drilling tools and other equipment, an ARO air operated diaphragm pump was an easy choice. We were able to supply a small 1” ARO pump that suited the customer’s needs perfectly. Word quickly spread to other mining operations in the area which generated more sales of the ARO product.

A western KY coal mine was looking for a small, portable, non-electric pump to remove water from mine shafts. The electric pumps that they would typically use for dewatering were cost prohibitive due to the IMSHA explosion proof safety guidelines that all mine operations must adhere to. Since air lines were already in the mine for drilling tools and other equipment, an ARO air operated diaphragm pump was an easy choice. We were able to supply a small 1” ARO pump that suited the customer’s needs perfectly. Word quickly spread to other mining operations in the area which generated more sales of the ARO product.