Case Studies

How we operate our company can help your bottom line.

CASE STUDY ONE

Multiply that by how many pumps they are running and you come up with some significant savings.

But more importantly, we now have a customer who knows we aren’t in this business to make a quick sale. We value relationships that, like some of our customers, have lasted 35 years. We look at the best solution that will be the least costly over time.

We have quite a few case studies on our website that share how we have solved problems and saved customers not only money, but down time as well.

Our job is to keep you up and running

CASE STUDY TWO

R. A. Ross & Associates has nearly 200 years combined experience

How we saved an auto parts supplier hundreds of thousands of dollars

How we saved an auto parts supplier hundreds of thousands of dollars

Chrome plating is a long, involved process and typically starts with degreasing, rinsing and cleaning, tedious polishing, then buffing, then acid dipping (etching), applying a metal catalyst then nickel and/or copper plating (many times calling for multiple layers) prior to the chrome plating itself. Typically the parts are rinsed in between each process.

As you can imagine, any particulate will show up as a defect and can’t be tolerated.

One auto parts manufacturer was encountering high costs and a severe problem with product reject rate. The rejects were due to particulate from their plating bath causing blemishes in the plating layer. The competitive bath filters were just not filtering their plating solutions properly and consistently.

We immediately involved one of our premium filter suppliers, Pentair Engineered Filtration. Pentair proved to be the perfect choice to develop the proper filter solution.

RESULTS

- Hundreds of thousands of dollars were saved due to lower scrap rate.

- The bottom line result was a competitive product with exceptional dirt holding capacities, precise filtration

ratings, repeatable performance, low pressure drops, and high efficiencies. Put our experience and knowledge to work to¬ward solving your problems. Our solutions may save you a lot of time, money and headaches.

Download the Case Study

Resources, Summit Pumps

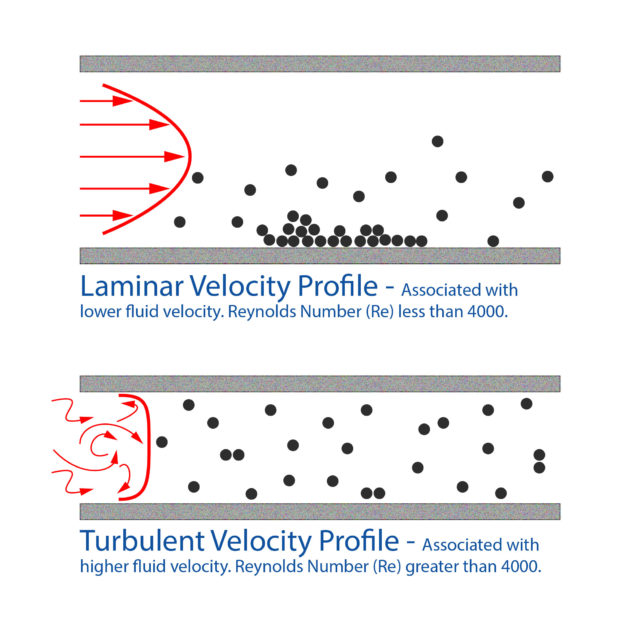

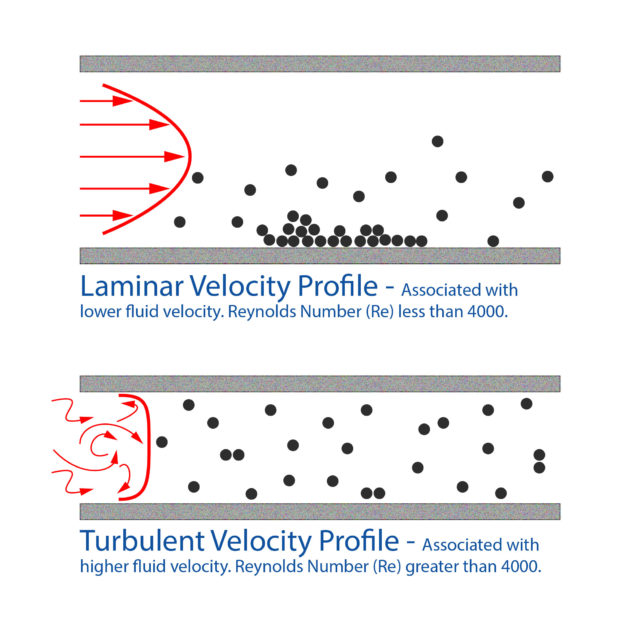

When pumping a slurry you need to be extremely careful concerning the fluid velocity in the piping.

When pumping a slurry you need to be extremely careful concerning the fluid velocity in the piping.

There is a critical carrying velocity for which if the slurry drops below this velocity, the particles will drop out of suspension. When the fluid and solids mixture drops below this velocity, due to gravity, the particles in suspension will have a tendency to drop out of suspension and accumulate in the bottom of the pipe. The critical carrying velocity is mostly dependent of the properties of the slurry.

Once the particles begin to accumulate in the bottom of the pipe, they will initially form a “sliding bed” of solids that will, eventually, completely block the flow; as if a valve was closed in the system.

The exact point where this will occur is difficult to predict. The clogging phenomena will vary with pipe size, type, internal surface roughness of the pipe, geometry of the system, solids concentration and the particular properties of the solids and the fluid itself.

Contrary to the industry best practices used in non-slurry applications; it is typically a good idea to have higher velocities and turbulent flow in slurry applications. This will help to prevent the fallout and blockage that can occur.

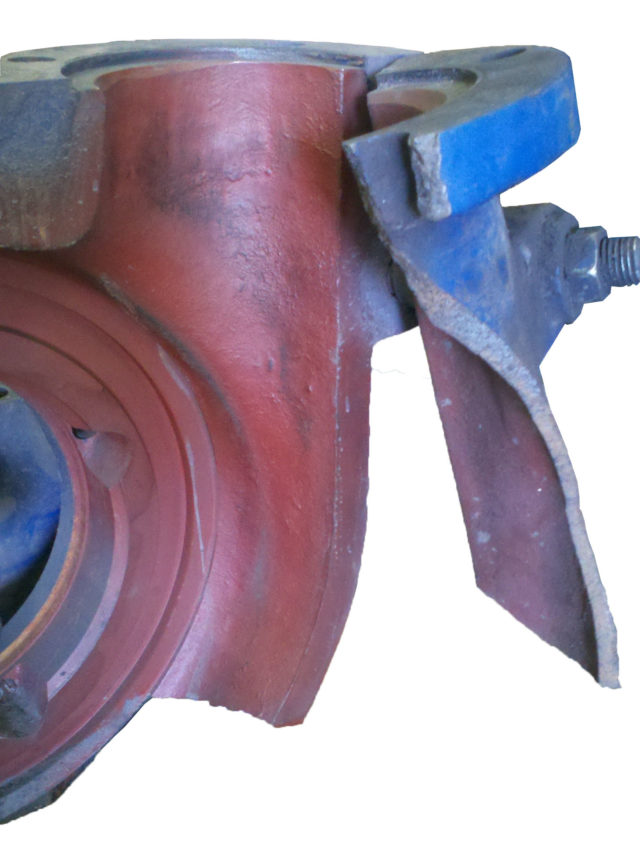

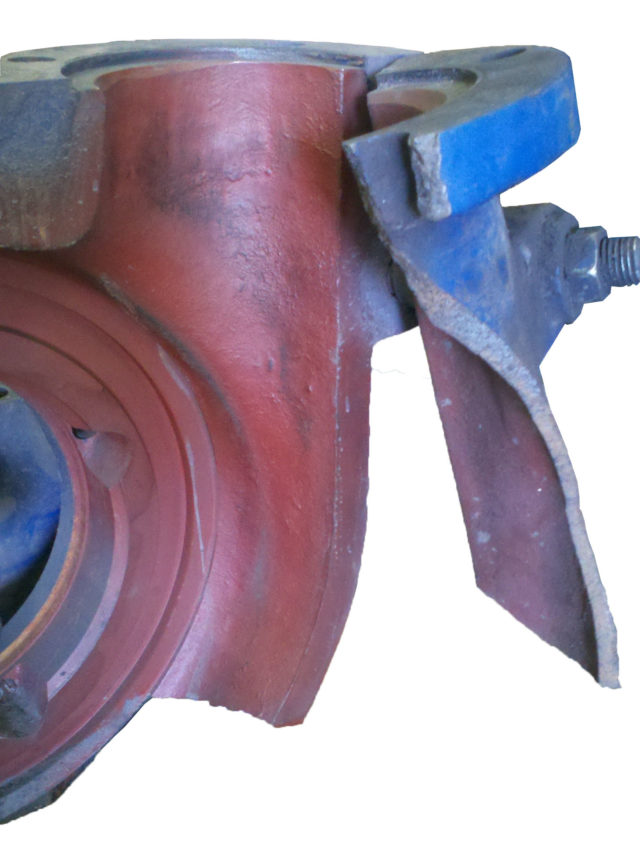

We see this issue occur more often when the pump is operated with a VFD to control the system. The VFD is controlled by a level manager, pressure, temperature and/or some other parameter that causes the pump to slow down. The velocity drops and the pipe clogs, but the pump continues to run.

Why is this important? Once the piping is clogged, it is similar to having both the suction and discharge valves closed off as now there is no flow and the solids continue to fall out of suspension. The pump continues to rotate with the fluid trapped in the casing, heating up the fluid to its boiling point and flashes to vapor. In other words, the pump explodes. This is not some urban myth, this can and does really happen.

Why is this important? Once the piping is clogged, it is similar to having both the suction and discharge valves closed off as now there is no flow and the solids continue to fall out of suspension. The pump continues to rotate with the fluid trapped in the casing, heating up the fluid to its boiling point and flashes to vapor. In other words, the pump explodes. This is not some urban myth, this can and does really happen.

-The Summit Pump Team

Learn More

Jim Elsey’s Pumps and Systems Articles

Featured

…if you didn’t have to clean your cooling tower two or three times a year?

Featured, news

To become a part of our product line, a product and manufacturer has to meet certain standards. After all, our company’s reputation rests not only on our team, our knowledge and service, but on the products we represent.

To become a part of our product line, a product and manufacturer has to meet certain standards. After all, our company’s reputation rests not only on our team, our knowledge and service, but on the products we represent.

QUALITY

An OEM with a formal Quality Assurance Program that incorporates general industry practices and ISO standards. (See complete details at summitpump.com/extras)

GREAT PRICING

Typically 20-25% savings, but up to 50% is not unheard of (depending on product).

PROVEN TRACK RECORD

Since 1982 Summit has manufactured quality pumps and pump parts for industry worldwide, and prides themselves on being the best value in the market.

AVAILABILITY

Over $11,000,000 worth of inventory in stock helps Summit react to emergency and rush orders.

RESPONSIVE

We know that when you need it, you need it now. Downtime is expensive. Summit is known for rapid response.

PARTS AND SHAFT KITS

Drop in replacements for Durco, Flowserve, Gorman Rupp, Goulds, Moyno, Worthington and more. All parts guaranteed to fit.

A few of the many models available:

|

|

|

Progressing Cavity

Capacities up to 4,500 GPM, pressures to 1,500 PSI. Drop in replacement for Moyno®, Tarby®, etc. |

SN Self priming

Capacities to 3,400 GPM, heads to 145 FT. Interchangeable with Gorman Rupp® T and Super T. |

SP Slurry Pumps Horizontal Split Case

Drop in replacements for Warman® HH. 24% chrome or rubber lined versions. |

|

|

|

DSR/DSN Horizontal Split Case

Capacities to 12,000 GPM, heads to 400 FT., stainless wetted parts optional. Interchangeable with Worthington® LN. |

CC & FM Closed coupled or frame mounted)

2” thru 10” sizes available, capacities to 3,400 GPM, heads to 145 FT. Stainless wetted parts optional. Drop in replacement for Peerless® C&F.; |

2196 ANSI*

Capacities to 6,000 GPM, heads to 730 FT, temperatures to 700°. Interchangeable with Goulds® 3196.** |

|

|

|

2175 Stock process pump

Capacities to 7,800 GPM, heads to 350 FT. Interchangeable with Goulds® 3175. |

|

|

Featured

Introducing a new member of our team…

Please welcome William Yarber to our inside sales team.

Please welcome William Yarber to our inside sales team.

William is joining us following nearly 14 years in the health care industry with Passport Health Plan and Evolent Health.

Prior, William worked for the Cabinet of Economic Development for the state of KY and as a loan processing branch and marketing manager.

William attended Mayfield High School and U of L.

At University of Louisville, William received his bachelors in Psychology with a minor in Business Administration. He also completed courses and was just short of his master’s degree in higher education administration.

William and his wife Colleen have three children and live in Simpsonville, KY. Feel comfortable to discuss any aspect of sports with William as he is an avid fan.

William’s email address is williamy@raross.com.

How we saved an auto parts supplier hundreds of thousands of dollars

How we saved an auto parts supplier hundreds of thousands of dollars

When pumping a slurry you need to be extremely careful concerning the fluid velocity in the piping.

When pumping a slurry you need to be extremely careful concerning the fluid velocity in the piping.

Why is this important? Once the piping is clogged, it is similar to having both the suction and discharge valves closed off as now there is no flow and the solids continue to fall out of suspension. The pump continues to rotate with the fluid trapped in the casing, heating up the fluid to its boiling point and flashes to vapor. In other words, the pump explodes. This is not some urban myth, this can and does really happen.

Why is this important? Once the piping is clogged, it is similar to having both the suction and discharge valves closed off as now there is no flow and the solids continue to fall out of suspension. The pump continues to rotate with the fluid trapped in the casing, heating up the fluid to its boiling point and flashes to vapor. In other words, the pump explodes. This is not some urban myth, this can and does really happen.

To become a part of our product line, a product and manufacturer has to meet certain standards. After all, our company’s reputation rests not only on our team, our knowledge and service, but on the products we represent.

To become a part of our product line, a product and manufacturer has to meet certain standards. After all, our company’s reputation rests not only on our team, our knowledge and service, but on the products we represent.

Please welcome William Yarber to our inside sales team.

Please welcome William Yarber to our inside sales team.