Tough applications and regulations are right up our alley

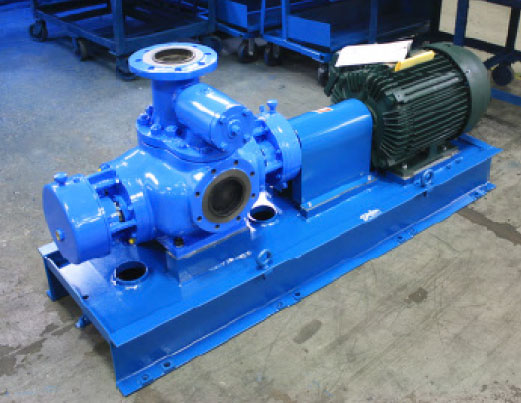

A major petroleum refiner in the mid-west came to R.A. Ross & Associates for a positive dis-placement pump solution for crude oil transfer. The customer needed a robust pump that could not only handle the crude oil, but also the design of the pump had to meet the stringent American Petroleum Institute standards (API-676) for rotating equipment used in the petroleum refining process. Additionally, the pump had to meet U.S. Department of transportation (DOT) standards because it would be connected to piping in a DOT area. R.A. Ross & Associates was able to offer a solution from Blackmer Pump Company who manufactures a positive displacement screw pump which meets the API-676 and the DOT standards. In addition to the pump itself, all of the components of the pump assembly had to meet the API and DOT specification as well, from the motor to the mechanical seal, to the base. If you have a tough regulation or tough application, let R.A. Ross & Associates find an easy solution!

Blackmer Screw Pumps are ideally suited for:

- Chemicals

- Caustics

- Adhesives

- Food & beverage

- Soap

- Petrochemicals

- Acids

- Polymers

- Crude oil

- Oilfields

- Asphalt

- Diesel

- Kerosene

- Lube oil

- Seawater

- Residuals

- Bulk transfer

- Loading/unloading

- Terminals

- Shipping

- Bilge and ballast

- Fire-suppression

How it works:

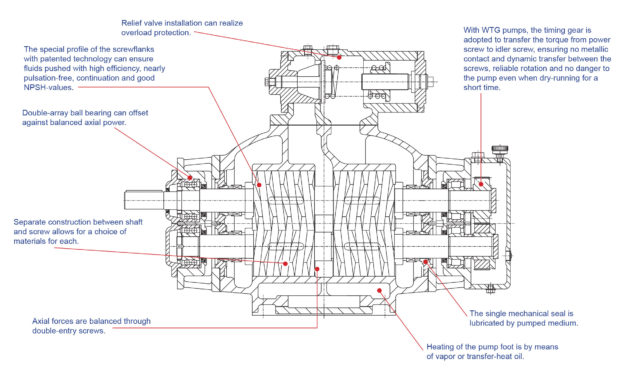

Blackmer Twin Screw Pumps are rotary, positive displacement pumps capable of handling various clean liquids that contain no solids.The pump is composed of two sets of opposed screws. During pump operation, the screws on the two shafts are engaged and form a sealed cavity with the surrounding pump casing.The pumped liquid is shifted axially as the screw shafts turn and steadily and constantly convey the liquid to the center of the pump where the discharge port is located. Since hydraulic forces on two screws are opposite and equal, the hydraulic axial stress on shafts is automatically balanced.