Once a year I attempt to remind all Summit Pump distributors of the “Plug and Play” myths

Once a year I attempt to remind all Summit Pump distributors of the “Plug and Play” myths

that unfortunately persist in the pump universe, like fake moon landings and that the earth is flat.

Please make sure you and others on your staff know these 5 key points:

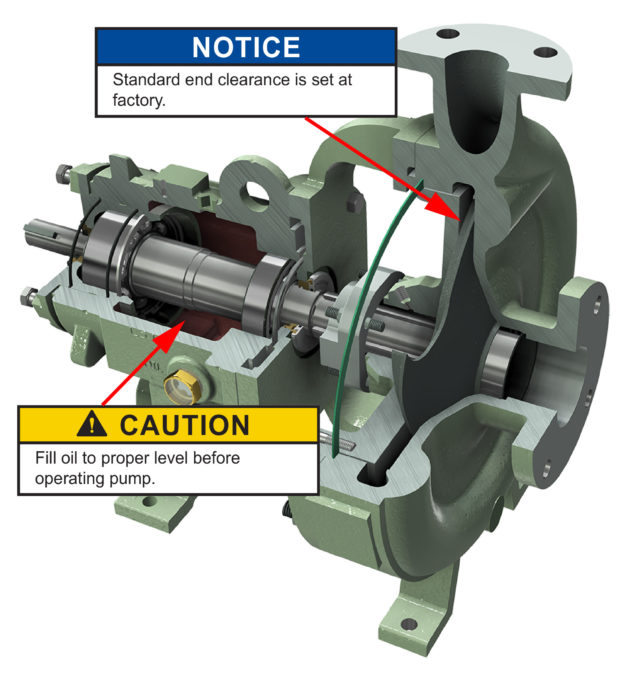

1) OIL: A Pump shipped from the factory does NOT have oil in the bearing housing.

Someone at the pump system site must set the proper amount of the proper oil prior to startup. It is a violation of several federal laws to ship oil in the pump, as oil is considered a hazardous substance.

2) IMPELLER clearance: Final impeller clearance must be set prior to startup. The factory sets the clearance at a nominal setting for the pump type and size, based on ambient temperature liquids, as the factory does not know the specific fluid temperatures or properties

3) MECHANICAL SEAL: A pump shipped from the factory does NOT have the mechanical seal set, in hopes of preventing damage to the sealing faces.

The seal should be set only after adjusting impeller clearance, pump alignment, and rotational checks have been completed

4) ROTATIONAL DIRECTION: A pump shipped from the factory will NOT have the coupling spacer installed because you must first complete the driver rotational check. Additionally having the coupling removed helps in the process to set the impeller and seal. We have a 50% chance of guessing your local electrical phase rotation. If we are wrong, the pump becomes scrap metal.

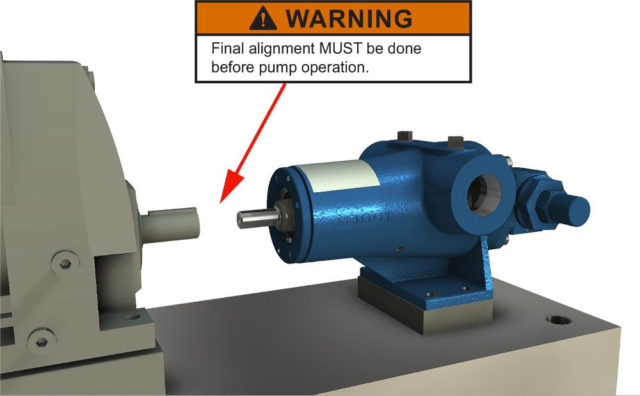

5) ALIGNMENT: A pump shipped from the factory will NOT be precisely aligned to the driver. The factory conducts/logs a rough alignment check during Assembly.

Even if we precision laser aligned the driver to the pump in accordance with NASA and USA Space Force standards, the very Nano-second the skid is picked up by a forklift or other device that alignment will disappear.

Note, that industry best practices (*1) dictate that a driver to pump alignment be checked/adjusted at least 5 times prior to startup. If you don’t know or are unsure about these 5 alignment stages, please check with your Regional Sales Manager.

A warning tag is attached to each pump to communicate these 5 key steps to the end user/installer. Of course these steps have always been stated in the IOM. The IOM is included with every pump, and can also be downloaded from our website in at least 5 languages.

Retort / Conclusion

Retort / ConclusionSeveral people have retorted that the competition does these 5 things and so their pumps are “plug and play”. I have checked with several knowledgeable and key sources at these competitive firms and that URBAN MYTH is simply NOT true.

As a matter of fact, the other OEMs state they have the same errors / issues with their end users not heeding the warnings on installation and startup.

Exceptions: I will venture to state that perhaps some distributors may offer these 5 key steps as part of their value package. If you do then you are best in class and get a gold star.

More than a minute… Extra Credit

Post Script: On a recurring basis we have people rotate ANSI pumps backwards, consequently that trips the motor on overload. Why? Because the impeller will unscrew and “mate” with the casing. The operator subsequently corrects the directional issue (phase rotation), but does not disassemble the pump to check and correct the resultant damage.

Please note that if the impeller has “mated” with the casing there is a very high probability (99%) that the impeller will require replacement, repair and or rebalance, the casing will also require repair, and the shaft is now bent beyond specification, further the bearings and mechanical seal have been mechanically shocked.

Rotation in the wrong direction is a costly mistake.

-The Summit Pump Team

Learn More Jim Elsey’s Pumps and Systems Articles