Open or Closed Tanks and the Effect on NPSHA Calculations

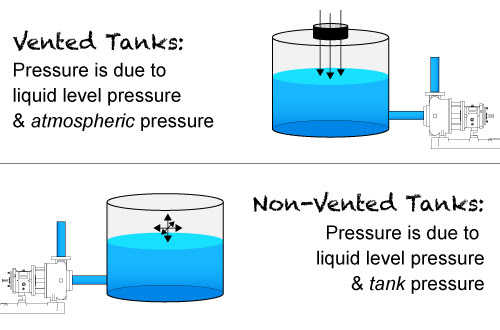

When working through NPSHA calculations for pump applications we need to know if the suction supply tank is open to the atmosphere or not. If it is an open tank the calculation is easy; as we just convert the ambient pressure to head for the first factor in the NPSHA calculation. Don’t forget to convert to absolute values and compensate atmospheric pressure for the local altitude above sea level. If the tank is closed, then we need to do a little more work converting the pressure or vacuum to absolute head for the calculation.

The Issue:

Often the customer will tell us the tank is closed to atmosphere, but it really isn’t; consequently the NPSHA calculations will be incorrect. The resulting NPSHA error will lead to a noncompetitive pump selection.

Sometimes the suction supply tank appears to be closed to atmospheric pressure, but if you look closer at the tank you will see it has breather valves installed. If there is a breather valve installed the tank pressure will always be very close to atmospheric pressure. It is very common, especially in the oil and gas world and also in the chemical and petro-chem arenas to use breather valves on the big bulk tanks. You may actually witness these breather valves on any size tank because the owner needs to protect the investment. Please realize these scenarios may also include rail tank cars, but do not confuse these examples with tank cars that are specifically designed to be pressurized or placed under vacuum for unloading purposes.

The Breather Valves Protect the Supply Tanks from:

- Overpressure (rupture) and or vacuum (implosion) issues

- Fire protection

- Evaporation; loss of product

- Corrosion protection

Another purpose is to prevent excess air and or water (plus other bad stuff like general pollution, O3 and NOx) from destroying the product integrity while it is in the tank. The purpose is to protect the product from outside influence and or to protect the outside environment from the product.

These protection/breather valves are normally required by EPA and or OSHA …they are not just a good idea, they are often a legal requirement in many product applications. Most tank owners apply the same rules to all of their tanks regardless of the product, tank size or location. Note that both the EPA and OSHA will defer to API 2000 for the selection and sizing criteria for the breather valves.

So…I Just Want to do the NPSHA Calculation, What Now?

If the tank has a breather valve, the answer is to simply use the local atmospheric pressure for the NPSHA calculations, because the actual tank pressure is going to be very close.

What if There is no Breather Valve and the Tank is Really Closed Off to Atmosphere?:

When you have a closed tank; I recommend you read my two Pumps and Systems articles on this subject from October and November of 2018, where the basics are covered.

https://www.pumpsandsystems.com/how-calculate-npsha-systems-under-vacuum

https://www.pumpsandsystems.com/calculate-npsha-closed-pressurized-system

If after reading you are still in doubt, call your RSM or engineering for assistance.

Last Comment:

Given a pump system with a supply tank open to atmosphere: note that on the suction line to an operating pump it is not uncommon to have a pressure lower than ambient. You may only expect this situation on a pump that is involved in a suction lift, but even for a flooded suction condition the suction pressure at the pump inlet can be at a vacuum. You can accurately calculate the actual pressure (vacuum) anywhere along the line by using Bernoulli’s Equation. Open and shut case… Easy peasy – lemon squeezy.

References:

OSHA 1910.106 July 1985

API 2000 Venting for Tanks 7th Edition 2014

API 12 (49 CFR 195.264)(b)(1) Specification for tanks

API 650 (CFR 132(b)(3) Specifications for large welded tanks

API Bulletin 2521 (Evaporation Reduction)

API Bulletin 2513 (Evaporation Losses)

EPA 40 CFR 112. Note: This regulation does not actually use the terms “aboveground storage tank.” Instead the term “bulk storage container”.

DOT (various/numerous with respect to rail cars)

-Jim Elsey