“Your pump isn’t producing enough flow!”

“Your pump isn’t producing enough flow!”

“I can’t get enough pressure out of your pump!”

“Your pump is making noise!”

We often get these calls from the field. While it is entirely possible, in reality,

it is rarely the pump’s fault.

From my almost fifty years of field experience with pump troubleshooting; I’ve found almost 80 percent of all centrifugal pump issues are on the suction side of the pump. I always start looking there first.

Key Data Needed, Prior to Calling Factory or RSM:

- Pump serial number.

- Fluid properties, or as I like to call it the “fluid personality”. (Temperature / Vapor Pressure / Specific Gravity / Viscosity / Suspended Solids / pH

- What condition was the pump sized for? Flow and head (differential head)

- What clearance is the impeller set at?

- What is the Shutoff pressure?

- Duty Cycle

- NPSHA?

- Submergence?

- Is the pump suction condition in a lift or flooded situation?

- Perhaps supply a sketch or photos of the system showing pipe size, elevations and components. “A picture is worth a thousand words”

- New application or replacement? If it’s a replacement pump, ask why they are replacing it.

The above data should be fairly quick and easy to get from the customer, using a Summit Pump Application Data Sheet. If you cannot solve the problem based on the above data, below are some more in-depth items to investigate further:

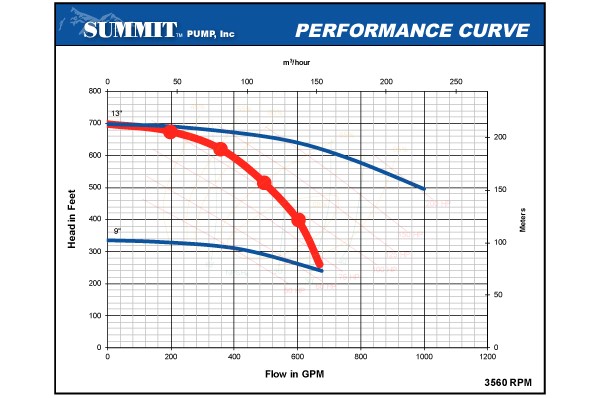

Sketch your pump’s performance against the Summit Pump performance curve.

Further Investigation:

- Confirm pump speed (RPM). This can be done with a tachometer. Be on the lookout for VFD issues, belt or engine driven installations.

- Confirm direction of rotation.

- Proper suction piping per ANSI/HI 9.6.6 guidelines. Proper pipe diameter, length and orientation is critical to successful pump/system operation

- Check the suction source. Is the tank too small, causing turbulence and high velocity? Is there entrained air in the liquid? Is there proper submergence?

- Gauges. Are the proper gauges installed? Are they calibrated?

- Suction lift conditions. Is the lift too high? What is the vapor pressure? Air leaks?

- Head & NPSHa Calculations. Confirm the head & NPSHa calculations. What is the NPSH margin? If the calculations are incorrect, the pump could be incorrectly sized for the application.

- Confirm liquid properties. Is the given information actually the liquid they are pumping? Did the process liquid change? (Specific Gravity, Viscosity, Temperature, Vapor Pressure)

- Pipe Strain. Is the piping properly supported? If not, pipe strain will usually manifest as hot bearings and alignment related issues. Was it laser-aligned?

- Parallel or Series Pumping. If not installed/operated correctly, pumps operating in parallel or series can have problems, and the pump(s) might not perform correctly.

Next Steps:

If you don’t know how to investigate these issues, and/or you are simply not comfortable with the process, we can assist, but please know that we are not system designers.