In the spirit of continuous improvement we like to occasionally remind our readers about important factors that are essential for a successful pump installation. Liquid properties such as viscosity has relatively little effect on positive displacement pump performance and in most cases makes them even more efficient, but viscosity is pure kryptonite for centrifugal (rotodynamic) pumps.

In the spirit of continuous improvement we like to occasionally remind our readers about important factors that are essential for a successful pump installation. Liquid properties such as viscosity has relatively little effect on positive displacement pump performance and in most cases makes them even more efficient, but viscosity is pure kryptonite for centrifugal (rotodynamic) pumps.

What is Viscosity?

Viscosity is that property of a fluid which tends to resist a shearing force. Simply stated; does it pour fast or slow …or how quick will a ball bearing fall through a vertical column of the liquid? You may also think of viscosity as the internal friction resulting when one layer of the fluid is made to move in relation to another layer. The viscosity of liquids will decrease as the temperature increases which is the opposite characteristic of gases.

Curve Corrections

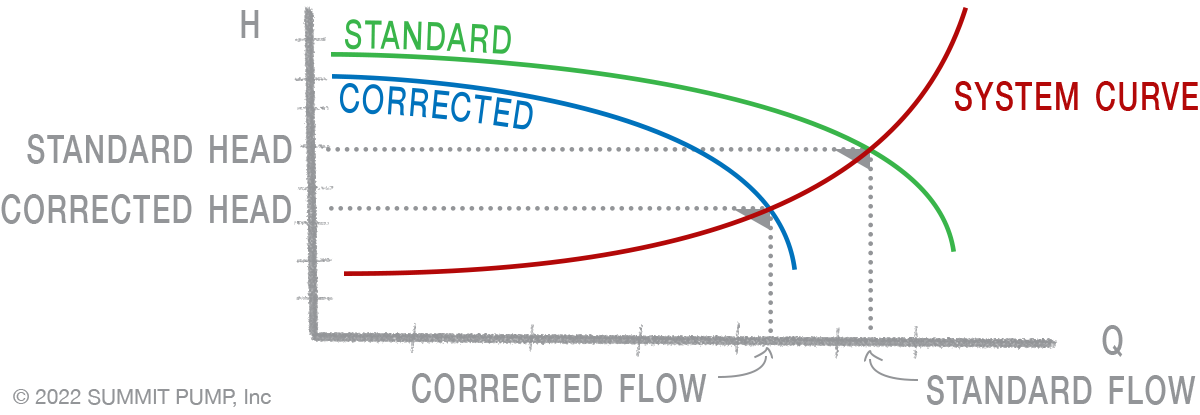

Centrifugal pump published performance curves are based on water and so when moving viscous fluids the performance must be corrected. Technically the pump performance curve should be corrected for viscosities above 5 centipoise (cps) which most people do not do. Please be advised that at viscosities greater than 40 centipoise it is no longer an option and the curve must be corrected. For viscosity corrections we use centipoise units. See Hydraulic Institute/ANSI standard 9.6.7 for more details.

As viscosity increases:

- Pump efficiency will decrease significantly

- Flowrate will decrease

- Developed head will decrease

- Power (bhp) required will increase

- NPSHR will increase and the NPSHA will decrease

- System curve will become more restrictive

- Affinity laws will become inaccurate

Centipoise vs. Centistoke

A simple way to explain the difference between these two terms is that…

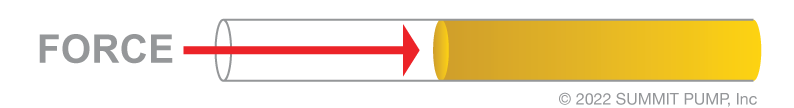

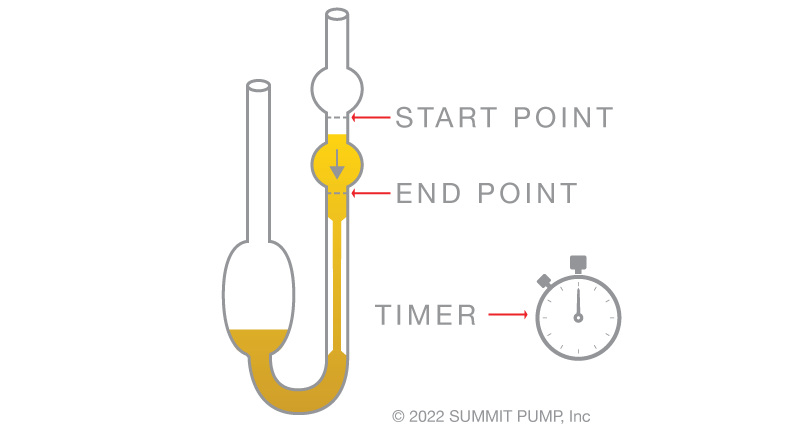

Centipoise: Dynamic viscosity is a measurement of the force required to overcome fluid resistance to flow through a tube (or capillary).

Centistoke: kinematic viscosities are timed flow rates through orifices where the driving force is typically gravity.

The relationship between Centipoise and Centistokes is proportional via the specific gravity.

Centistoke = Centipoise ÷ Specific Gravity

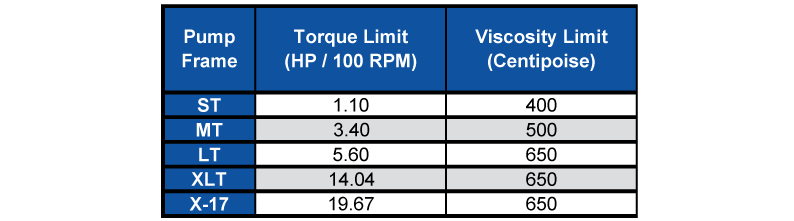

Pumps Have boundaries

All pumps have limits as to how much horsepower can be utilized. This boundary is based on power frame (shaft and bearing) speed versus torque limits and is normally expressed in BHP per 100 rpm terms.

Note: These stated limits are based on direct drive and must be reduced for belt or engine drive. See engineering for assistance.

Maximum Limit: Should you need to pump liquids at higher viscosities please contact us to review the application. Viscosities above 2000 – 2500 centipoise must be handled with positive displacement pumps.

Caution: Do not apply the Affinity Laws directly to viscosity performance corrections. You must first correct the viscous performance to its equivalent water performance before the Affinity Laws are applied. Once you have determined the new water performance then the viscous correction factor can be applied to estimate the new viscous performance.

Good news: All of these required viscosity calculations can be easily accomplished in a few keystrokes on Summit Select.