I am frequently asked; should the discharge valve be open or closed when the pump is started? My answer is….it depends, but regardless the suction valve better be open.

First Things First

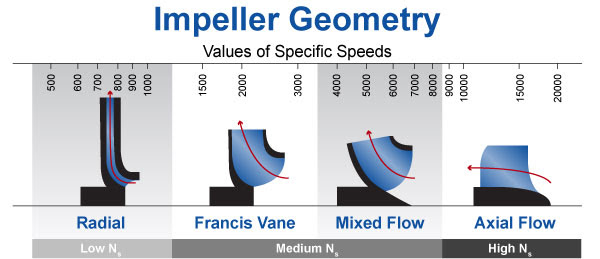

Let’s look at the impeller. There are many things to consider, but the primary question we want to answer today is; what is the geometry of the impeller? From that shape we will determine the range of Specific Speed (NS). Ok, I may have lost you now because I used the nerdy “Specific Speed” term, but let me explain. Just for today’s purpose, let’s focus on the directional path of the liquid and specifically how it enters and exits the impeller.

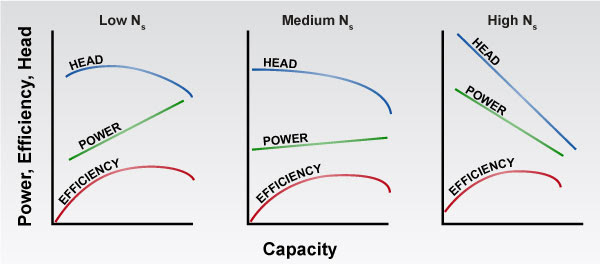

Specific Speed is a predictive indicator for the shape of the curves for head, power and efficiency.

Low Ns

If the liquid enters the impeller on a path parallel with the shaft centerline and exits the impeller at an angle 90 degrees to the shaft centerline (at a right angle) then the impeller is in the low Specific Speed range. This would be a typical radial impeller like the Summit Pump model CC-FM.

Medium Ns

If the liquid enters the impeller on a path parallel with the shaft centerline and exits somewhere close to a 45 degree angle, then the impeller is in a medium Specific Speed range. These are mixed flow or Francis-Vane type impellers.

High Ns

If the liquid enters the impeller on a path parallel with the shaft centerline and exits in a path parallel to the shaft centerline, this is a high Specific Speed impeller. This axial flow type of impeller would look similar to a boat or airplane propeller.

Plan B

Don’t know the Specific Speed (Ns) of the impeller? Ask the manufacturer.

Now for the Really Interesting Part

For low Specific Speed (Ns) pumps the Brake Horse Power (BHP) required increases as you open the discharge valve and increase the flow rate, this is a direct relationship just as you would intuitively expect. For medium Ns pumps the BHP curve and its maximum point moves back to the left some nominal amount … in the past you may have not noticed this change. Axial flow pumps, of high Ns, the BHP is near its maximum point at the lower flow rates and actually reduces as the flow rate increases. Perhaps the opposite of what you would expect? Notice how the slope of the power graph also changes when the impeller design goes from low to high specific speed.

And…Answering the Original Question

I recommend that the discharge valve be closed on the startup of low Ns pumps and to be open on high Ns pumps. Note, this is a “thumb rule” and there are numerous caveats that can and will modify the answer.

- If the low Specific Speed (NS) pump is of any consequential size (Flow, Head and BHP) you may need to have the discharge valve slightly open to reduce the differential pressure across the valve. This step will minimize the effort to open the valve. Some pump systems will have a bypass line for this purpose.

- Systems that have downstream pressure (from another source) with no check valves (or check valves that are leaking by) can force the pump to spin backwards when the discharge valve is open.

- If you are starting a pump that will operate in parallel with another pump(s) you need to consider check valve lift points and controlling instrumentation (PID); this is a subject too cumbersome to explain in the “Sixty Seconds” platform.

- Normally, high Specific Speed (NS) pumps are started with the discharge valve open to reduce the electrical load and resultant stresses on the driver. In many cases the driver may not be adequately sized (on purpose) to handle the low flow power requirements and will trip offline.

-Jim Elsey