Major natural gas company now has less filter clogging and increased production

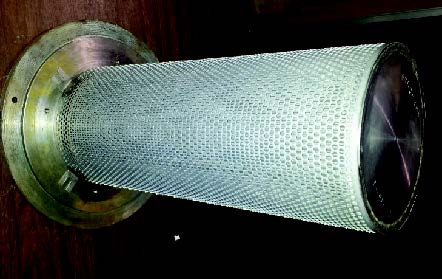

Our pleated filter solution doubles the filter surface

area, while our perforated mesh cover increases

flow and prevents the filter element from clogging.

Problem: Our customer, a major natural gas company refinery, had problems with filter elements clogging

and elements not working efficiently. This increased their downtime and decreased the production.

We were able to replicate the customer’s design. However, we created a pleated mesh filter with a higher micron rating with a perforated shell to increase flow and prevent elements from clogging up quickly.

Not only did we provide a custom filter that would work more efficiently, we were also able to fabricate this filter locally and saved the customer downtime and costs.