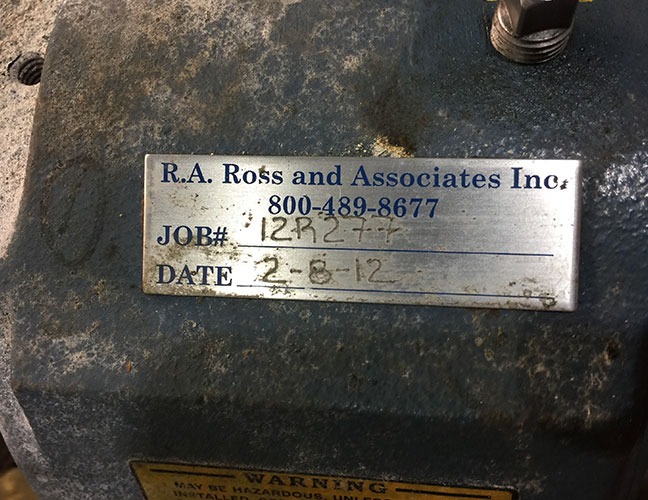

This little tag tells an incredibly

valuable story.

2012.

That’s the last time we repaired this pump.

Our repairs normally last years, even with the abuse some of these pumps have to take day in and day out. And the 5 year example in this case is pretty typical.

Case in point

In February of 2012, a customer needed their Dean ANSI pump repaired. Our repaired pump made it 5 years before needing work!

“These guys go above and beyond!”

Gary Morrison

Maintenance Planner

Catalyst Division

Clariant Corporation

What do we do differently?

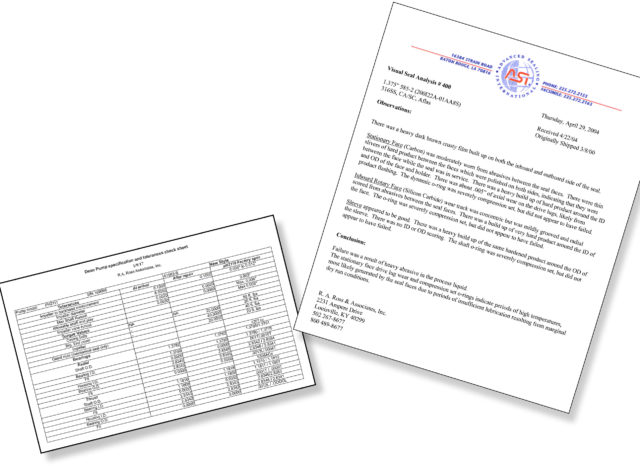

Look at the check list (below). Upon receipt, the problem pump is checked and each dimension and value is documented. This gives us a baseline as to the extent of repairs needed. Any component that is not within specification is recommended to be replaced or repaired. Then after authorization to repair, the replaced or repaired components (and finished complete assembly) is rechecked to verify all meet factory recommended specifications.

If a customer desires or something non-typical occurs, pictures of the subject part or parts are taken and furnished to the customer.

Not everyone or every repair needs this level of detail, but we can provide it if you desire.

We not only can bring pumps and parts up to OEM specs, we often surpass those specs, including dealing with tolerances within 1/10,000 of an inch.

We’ve even gone so far as to make duplicates of hard to find parts.

Attention to detail

No repair leaves our shop without passing a rigorous checklist. This attention to detail will save you valuable downtime and money.

If you want it repaired right,call us. We’ll arrange shipping, work up estimates and turnaround time, and call you with any concerns about future issues or why your pump or pump parts failed (see evaluation at upper right).

Download the case study

SN169066 ASI analysis

Tolerance Sheet Table 1