Pump Alignments

We all know that proper

Warning: All pumps must be final aligned in the field. No matter how precise the alignment from the factory, it will be lost when the unit is shipped and installed.

Baseplates: Flat and Level

Baseplate flatness has become an issue in recent years as customers are looking to simplify installation and alignment and reduce MTBF (mean time between failures), while attempting to also reduce costs.

Most of us understand that the pump baseplate has to be level. The biggest reason for that criterion is the oil level in the bearing housing. It is possible to have too much oil on one bearing (for example the radial bearing) and not enough on the other bearing (thrust bearing). If the proper oil level is the middle of the bottom ball then it doesn’t take a whole lot of “being un-level” to miss this crucial mark.

What is flat?

A typical fabricated steel baseplate for an ANSI or standard industrial pump will be flat to within 0.005 inches (0.127 millimeters) per foot (0.3048 meter).

Example: If the distance between the pump mounting pad and the motor mounting pad is 4 feet (1.2192 meters), then the motor pad can be 0.020 inches (0.508 millimeters) higher or lower than the pump pad. If a pump pad is one foot (0.3048 meter) long, it can be 0.005 inches (0.127 millimeters) lower or higher on one end.

Process Industries Practices (PIP) (and API610) bases for the same model can be 0.002 inches (0.0508 millimeters) per foot (0.3048 meter), or less than half of the standard baseplate.

Benefits

A flat surface will allow the installer to more effectively level the baseplate prior to grouting and then align the motor to the pump by shimming under the motor feet. When attempting to align the pump and motor shaft to within 0.002 inches (0.0508 millimeters) TIR (Total Indicator Run-out), it is easier to start out on a level playing field rather than have unequal shim stacks under each foot of the motor.

Extra Credit:

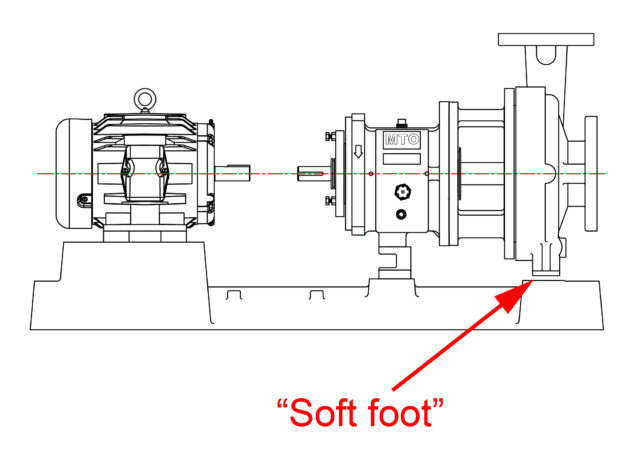

Good millwrights and pump technicians/mechanics know to check for *soft-foot before they start the pump to driver alignment.

*“soft-foot” is where one or more feet are not in contact with the mounting pad when the unit is in the unbolted condition (this should be corrected by shimming, not by tightening the bolt which may distort the motor frame).

If you had a soft-foot of 0.016” and then bolted the motor down anyway; you have just introduced 0.008” of strain/stress into the driver. There is now potentially 0.008” of offset between the front and rear bearings, regardless of the motor size. If you do a similar offset to the pump, again you have introduced an internal stress on the bearings and shaft. Even without soft-foot on either pump or motor, if the baseplate is not flat, you have just done the same thing to the driver and or motor. Bases must be level and flat.

-The Summit Pump Team

Learn More Jim Elsey’s Pumps and Systems Articles