Ross solution saves customer $8,000 and 6 weeks on delivery

APPLICATION:

APPLICATION:

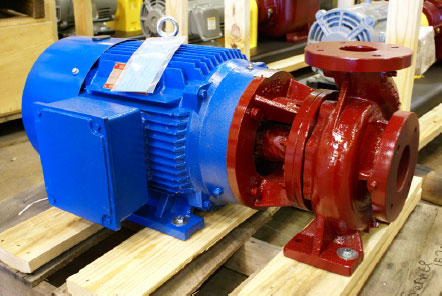

Cooling water at 220GPM @ 27’tdh Our customer had a KSB pump that was in need of replacement and had a quote in hand from a competitor for a pump assembly costing $10,000 with about an 8 week lead time. They requested we quote an alternative product that they could get within 4 weeks of ordering around the same price or better. We were able to do both beating the leadtime of the original quote by 6 weeks and price by almost $8000!

We didn’t have much to go on as we did not have any information on the KSB pump other than what was on the tag. Fortunately the tag had the process conditions of 220gpm @ 27’ tdh. We confirmed the conditions during onsite visits with the customer and provided our quote for the American Marsh 300 REC series pump based on these conditions.

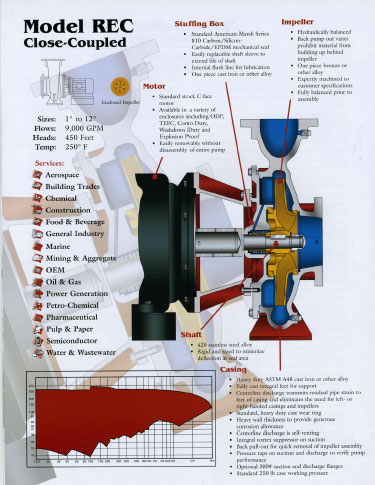

The pump we proposed was a close coupled pump rather than a frame mounted configuration saving the customer precious space as the pump was going into some tight quarters. The American Marsh pump only required minimal piping changes to the existing system and the smaller size we provided gave the customer more flexibility in piping modifications. With The condition point required of the pump required a full diameter impeller and landed at 92.39% of the BEP also making this a much more efficient pump than the existing or competi-tor’s offering.

The pump we proposed was a close coupled pump rather than a frame mounted configuration saving the customer precious space as the pump was going into some tight quarters. The American Marsh pump only required minimal piping changes to the existing system and the smaller size we provided gave the customer more flexibility in piping modifications. With The condition point required of the pump required a full diameter impeller and landed at 92.39% of the BEP also making this a much more efficient pump than the existing or competi-tor’s offering.

With an $8000 savings over the existing quote option the customer had, a lead time of 2 weeks, minimal piping changes required, improved efficiency, and standard pump features like carbon vs. silicon carbide mechanical seal and stainless steel fitted construction, the customer ordered 3 of the pumps deciding to replace all of the KSB pumps they had in this same service.