Here are some brief reminders about NPSHA and NPSHR.

NPSH changes with:

Clearance of impeller and wear rings: As clearances open up on the pump over time the NPSHR will also increase. This effect is significantly worse for closed impellers than open or semi open styles.

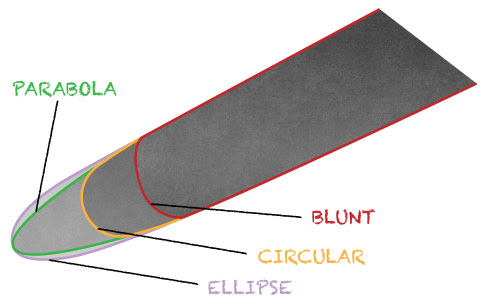

Vane geometry: Specifically the leading edge profile of impeller vanes. The shape of the leading edge will affect NPSHR. Vane geometry in order of best shape to worse shape are 1) parabola 2) ellipse 3) circular 4) blunt.

Viscosity: Yes an increase in viscosity will increase the NPSHR and decrease the NPSHA. There must be a correction for viscous fluids. In one simple word … friction. See note at bottom for more info.

Air Entrainment: Air entrainment in a range of 0.3 to 1.0 percent will actually work to help the NPSH issues, but above 1% the NPSHR will increase.

Air Entrainment: Air entrainment in a range of 0.3 to 1.0 percent will actually work to help the NPSH issues, but above 1% the NPSHR will increase. Suction pipe geometry: For every elbow, twist and turn in the suction pipe the fluid velocity profile becomes turbulent (technical for; it gets all messed up) and creates a mismatch (discrepancy) between the fluid velocity and the impeller inlet vane velocity. This mismatch creates recirculation at the impeller eye that directly affects NPSHR.

Suction pipe geometry: For every elbow, twist and turn in the suction pipe the fluid velocity profile becomes turbulent (technical for; it gets all messed up) and creates a mismatch (discrepancy) between the fluid velocity and the impeller inlet vane velocity. This mismatch creates recirculation at the impeller eye that directly affects NPSHR.NPSH Margins: Last; please understand that pumps with adequate NPSH (calculated) margins…where NPSHA exceeds NPSHR can still cavitate, because the margins are not sufficient and the system dynamics are changing.

Quiz: On your own…see if you understand why the following factors affect NPSH.

- Temperature both ambient and fluid

- Vapor Pressure

- Specific Gravity of the fluid

- Elevation above sea level

Bonus Info:

Pumps require a certain amount of Net Positive Suction Head (NPSH) to operate satisfactorily at a given point of head and flow on the curve to prevent cavitation. These points are empirically determined by the manufacturer (sometimes calculated) and are denoted as Net Positive Suction Head Required (NPSHR).

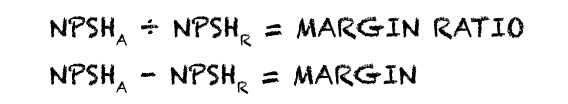

The suction side of the system itself must in return provide a certain amount of NPSH and that is referred to as Net Positive Suction Head Available (NPSHA). There must be more NPSHA than NPSHR for the pump to operate satisfactorily. The difference is referred to as the margin or ratio.

Refer to Hydraulic Institute 9.6.1-2017 for details on margins and ratios.

Viscosity: ANSI/HI Standard 9.6.7- 2015 provides updated instructions for correcting a known water performance into an estimated viscous performance for a given viscosity.

-The Summit Pump Team