Some people still think they can align a pump with a straight-edge, in lieu of a laser or dial-indicator method. They are incorrect. While a straight-edge alignment can potentially kill your bearings, seals and couplings, it also consumes extra horsepower.

Some people still think they can align a pump with a straight-edge, in lieu of a laser or dial-indicator method. They are incorrect. While a straight-edge alignment can potentially kill your bearings, seals and couplings, it also consumes extra horsepower.

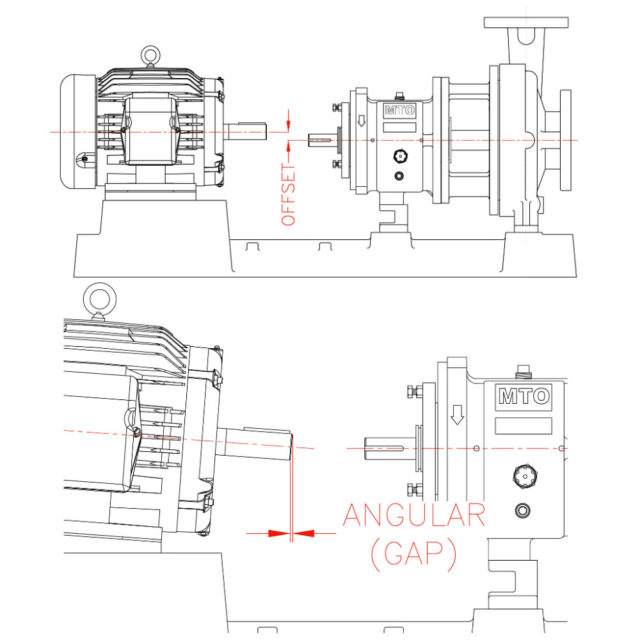

Recent studies show that a simple 0.050” offset, which is about the best straight-edge alignment possible, will consume 9% more power.

An angular misalignment of 0.015” gap per inch of shaft diameter will consume 6% more power.

At least once a month, we will receive a complaint that our pump is not aligned to the driver upon site arrival. We try to advise our distributors that the final alignment must be performed in the field. An initial rough alignment is done at the factory to prove that the unit is able to be aligned, but as the pump is transported, the unit will become out of alignment. Pump units should be alignment checked five different times during the course of the installation. (We will cover that subject another time.)

At least once a month, we will receive a complaint that our pump is not aligned to the driver upon site arrival. We try to advise our distributors that the final alignment must be performed in the field. An initial rough alignment is done at the factory to prove that the unit is able to be aligned, but as the pump is transported, the unit will become out of alignment. Pump units should be alignment checked five different times during the course of the installation. (We will cover that subject another time.)

Also, note on existing installations you would never move the pump, only the driver. Although, on new installations before the piping is brought to the pump, it is perfectly acceptable and sometimes necessary to move the pump within the room allowed by the bolt holes.

-The Summit Pump Team

Learn More Jim Elsey’s Pumps and Systems Articles