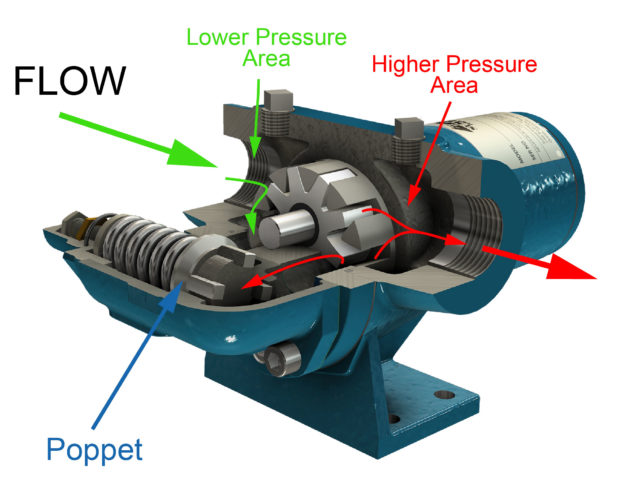

Each of Summit Pump’s Internal Gear Pumps come standard with a pressure relief valve. These valves are designed and positioned to protect the pump by SAFETY means only; they are not meant for throttling the flow or pressure of the system.

Each of Summit Pump’s Internal Gear Pumps come standard with a pressure relief valve. These valves are designed and positioned to protect the pump by SAFETY means only; they are not meant for throttling the flow or pressure of the system.

When the system pressure is increased and the pressure relief valve is opened, possibly due from a blocked pipe or closed valve, it recirculates the fluid within the pump via the valve. Even though this avoids building pressure in the system.

The heat generated by the moving parts of the pump has nowhere to go, except into the pump materials and the recirculating fluid. This can become problematic for a few reasons:

- The pump materials expand, closing the specially designed clearances for the application, pump, model and size potentially causing the pump to lockup.

- The vapor pressure of the fluid increases, lowering the NPSHa past NPSHr causing the pump to cavitate, causing damage to the casing, rotor and/or idler.

- The fluid flashes in the valve. This means the fluid rapidly expands potentially exploding the pump and/or valve. This is even more critical with fluids with low boiling points (saturation temperatures), such as propane or ammonia, as flashing will happen at lower temperatures, depending on suction pressure.

There should always be other means of pressure relief in the system. Switches and alarms should also be installed if the pressure relief valve to were ever open. Measuring flow in the discharge is a good way of doing this.

There should always be other means of pressure relief in the system. Switches and alarms should also be installed if the pressure relief valve to were ever open. Measuring flow in the discharge is a good way of doing this.

The valves are set to a standard pressure based on the pump model and size, unless otherwise specified on your purchase order.

–The Summit Pump Team