When pumping a slurry you need to be extremely careful concerning the fluid velocity in the piping.

When pumping a slurry you need to be extremely careful concerning the fluid velocity in the piping.

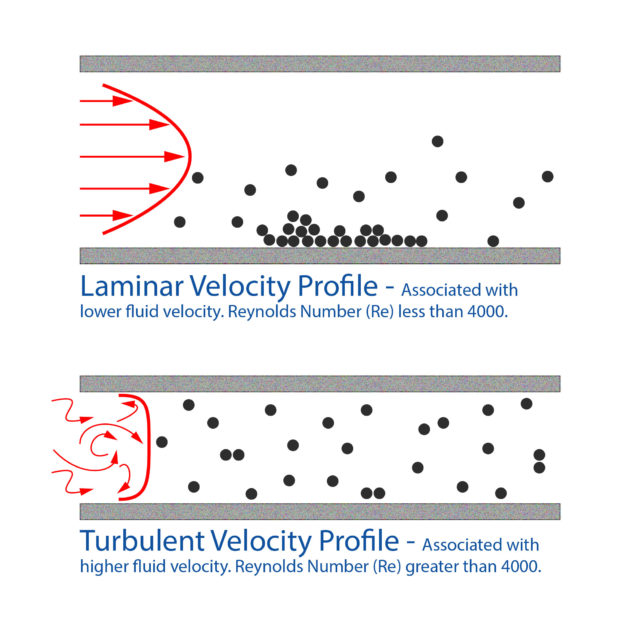

There is a critical carrying velocity for which if the slurry drops below this velocity, the particles will drop out of suspension. When the fluid and solids mixture drops below this velocity, due to gravity, the particles in suspension will have a tendency to drop out of suspension and accumulate in the bottom of the pipe. The critical carrying velocity is mostly dependent of the properties of the slurry.

Once the particles begin to accumulate in the bottom of the pipe, they will initially form a “sliding bed” of solids that will, eventually, completely block the flow; as if a valve was closed in the system.

The exact point where this will occur is difficult to predict. The clogging phenomena will vary with pipe size, type, internal surface roughness of the pipe, geometry of the system, solids concentration and the particular properties of the solids and the fluid itself.

Contrary to the industry best practices used in non-slurry applications; it is typically a good idea to have higher velocities and turbulent flow in slurry applications. This will help to prevent the fallout and blockage that can occur.

We see this issue occur more often when the pump is operated with a VFD to control the system. The VFD is controlled by a level manager, pressure, temperature and/or some other parameter that causes the pump to slow down. The velocity drops and the pipe clogs, but the pump continues to run.

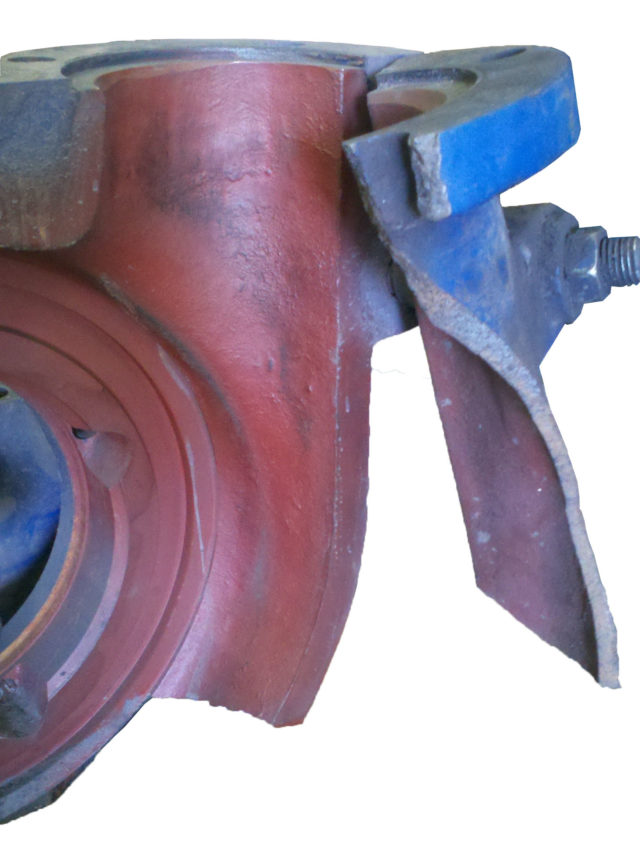

Why is this important? Once the piping is clogged, it is similar to having both the suction and discharge valves closed off as now there is no flow and the solids continue to fall out of suspension. The pump continues to rotate with the fluid trapped in the casing, heating up the fluid to its boiling point and flashes to vapor. In other words, the pump explodes. This is not some urban myth, this can and does really happen.

Why is this important? Once the piping is clogged, it is similar to having both the suction and discharge valves closed off as now there is no flow and the solids continue to fall out of suspension. The pump continues to rotate with the fluid trapped in the casing, heating up the fluid to its boiling point and flashes to vapor. In other words, the pump explodes. This is not some urban myth, this can and does really happen.

-The Summit Pump Team

Learn More Jim Elsey’s Pumps and Systems Articles